Couple of shots of the cars

Anyway, I thought I would tell you about an incident I encountered.

I came up to this area where water was covering the track around a corner. I was lining myself up to take the chicken track… But then chris (from the disco behind me) came out with the camera keen to get a photo of me going through the water… So after some hesitation I decided I would do it.

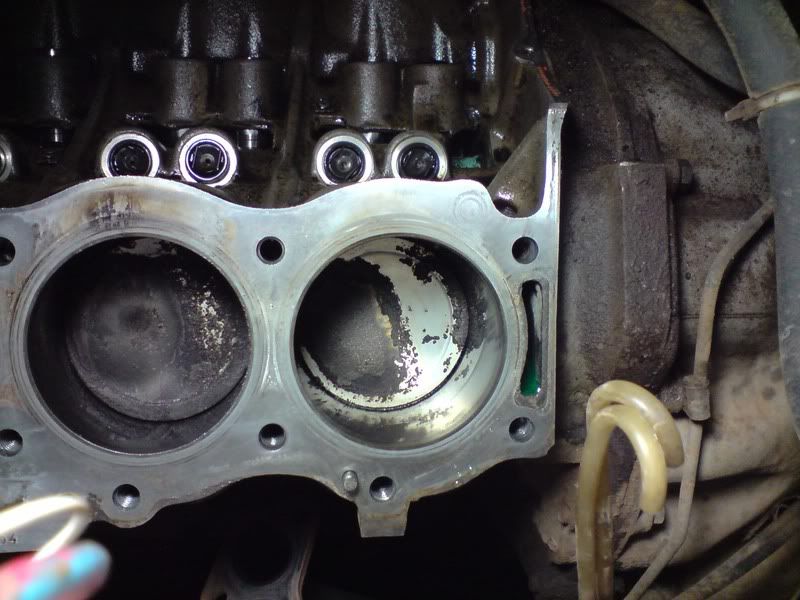

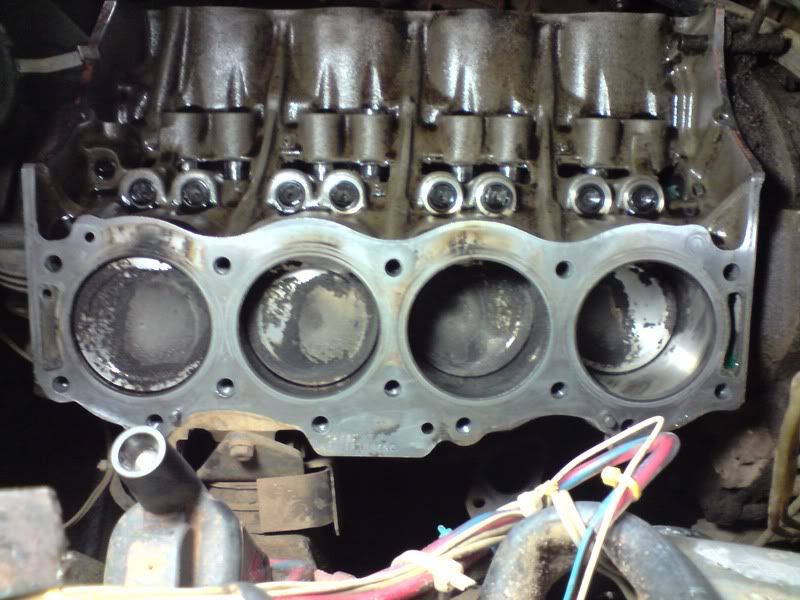

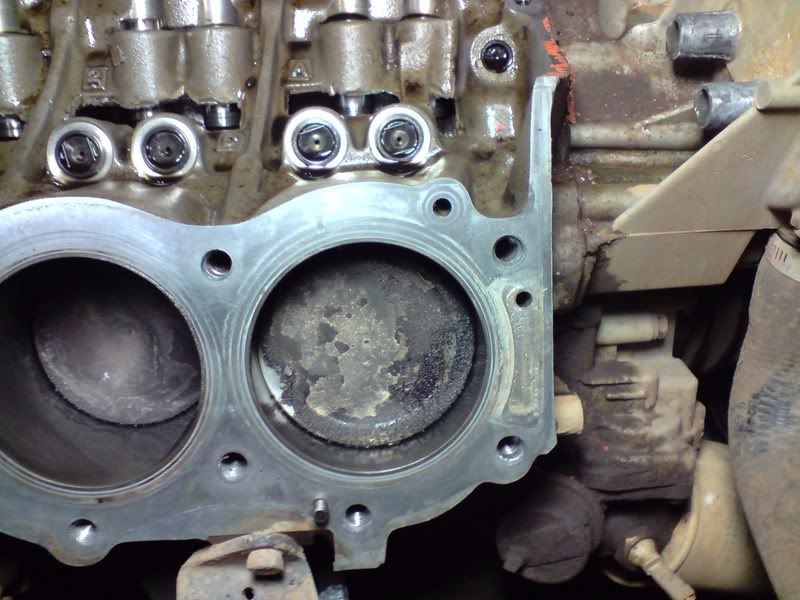

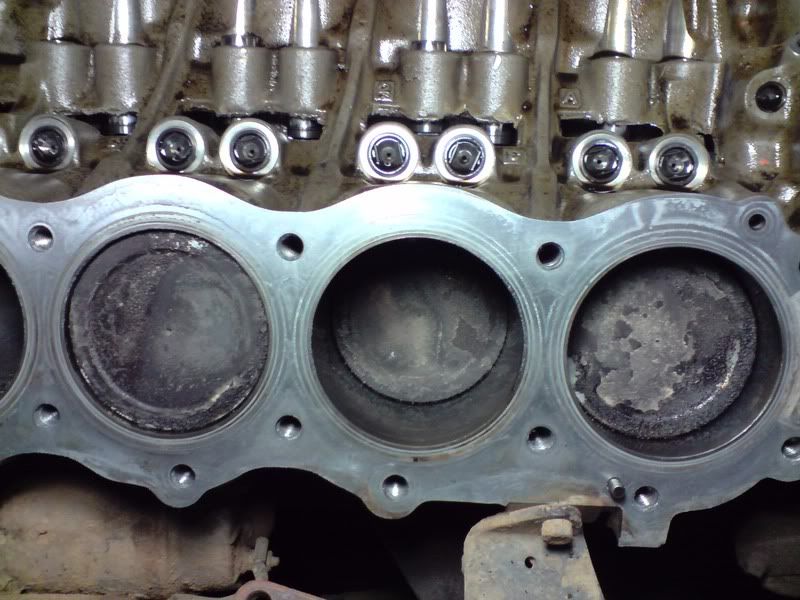

So I drove in not expecting much, I intended to keep my LH tyres on the dry section and have my RH tyres ride the centre ridge. Anyway I drove in to find that the track dropped away and I suddenly found the car practically on its side. A few seconds later I was sitting in water and I felt the car continue to roll right. I had a female friend in the car (she was my navigator) and she didn’t’ say a thing in shock. At this point all we wanted to do is get out of the car before it rolled over. We eventually got the top side door open and I found myself standing on the under water door and my head poking out the other. Stuart (driver of a very decked out rangie) had jumped onto the LH rear wheel and was using his body weight to prevent the car rolling onto its side. Pretty soon everyone was latched on. At this point the engine had cut out and I figured I should try to get the engine started. I was eventually able to fire it up with half the motor under water and chris hooked his winch up to my rear recovery point. Obviously none of this would have happened if I checked how deep the water actually was.

I was soaked and everyone thought it was very funny and started taking photos of me while I was emptying my boots.Anyway, we eventually headed off and continued along the track to finish the day at around 3pm. So anyway the photos.